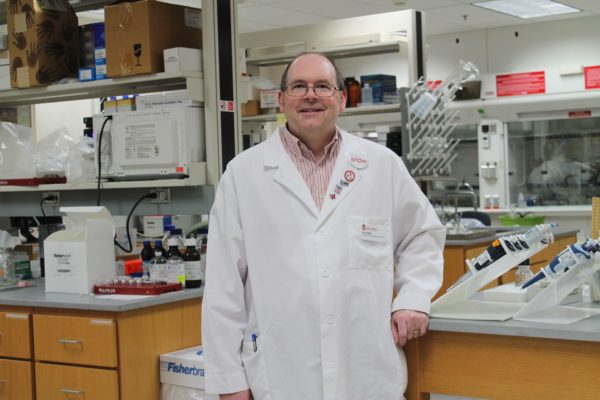

Zeeh Pharmaceutical Experiment Station partners with UW Health Pharmacy Services to provide vital supplies for healthcare workers

By Katie Ginder-Vogel

With hand sanitizer in short supply around the world during the COVID-19 pandemic, the UW–Madison School of Pharmacy’s Zeeh Pharmaceutical Experiment Station team is producing hand sanitizer for UW Health. Although the Zeeh Station focuses on supporting drug development, it offers the capabilities and facilities to meet the need for hand sanitizer for UW Health Pharmacy Services, its long-time partner on previous projects.

School of Pharmacy alumnus Jerame Hill (MS ’16), director of pharmacy supply chain for UW Health, says it’s essential to have the sanitizer available. “If it wasn’t for this, we really wouldn’t have anything to protect both our patients and our employees,” Hill says. “So this is vitally important that we have this available.”

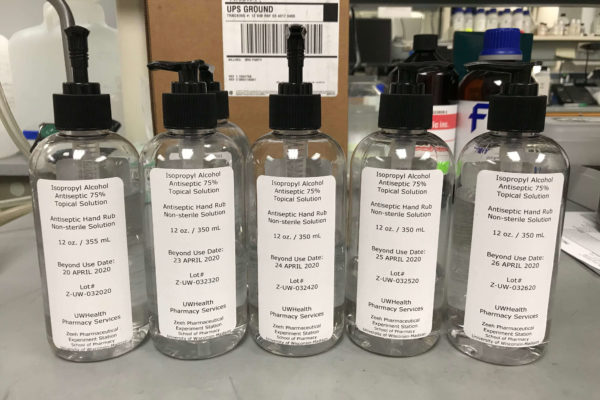

Zeeh Station Director Ed Elder and the team started production on March 20, and in less than a week, they provided more than 100 gallons of hand sanitizer. The goal for daily production is about 10 batches of hand sanitizer at 10 liters per batch. That’s about 300 12-ounce bottles, a bottle size specifically needed by University Hospital.

“During this pandemic, we’re proud to do our part in helping protect healthcare workers who are on the front lines of this public health crisis,” says Steven Swanson, dean of the School of Pharmacy. “The expertise of our Zeeh Station is especially valuable, and the team moved quickly to convert operations to compound hand sanitizer while maintaining safety in the lab.”

Making “Badger-ell”

The hand sanitizer is made from four ingredients: alcohol, hydrogen peroxide, glycerin, and water. The formulation is based on World Health Organization (WHO) recommendations that have been incorporated into FDA and U.S. Pharmacopoeia (USP) guidelines. Ed Elder, who holds a PhD in pharmaceutical sciences and is also a licensed pharmacist, serves on the USP Compounding Expert Committee, so he was actually involved in developing that guidance.

Watch how the hand sanitizer is made for UW Health and University Hospital.

“It’s less viscous than commercially available products,” says Elder. “It’s a solution, not a gel, with a higher alcohol content than commercially available gels.”

The WHO recommends a high alcohol content because if hand sanitizer is being compounded in a developing country, a higher concentration can kill off any bacteria in the water.

“The WHO recommends using boiled water in production, but we’re fortunate enough to have high purity water right in our lab,” Elder says. “Also, the bottles being used haven’t been tested yet to see how quickly alcohol evaporates from them, so higher alcohol content ensures the product will be good for the allowable 30-day shelf life.”

Elder’s team is testing the product over time while it’s in use, to generate data that will hopefully help extend shelf life.

“Each day, we test a sample, to make sure it’s where it’s supposed to be,” Elder says. We’re using the same test to evaluate its potency over time, and we also check it visually over time.”

The team follows their usual rigorous documentation process: Raw materials get logged into a spreadsheet on a lab computer, and each lot of material is assigned a lab code for traceability. Through the Zeeh Station’s quality review system, all paperwork is verified, and the potency of the product is measured daily.

UW Health procures the sanitizer raw materials, including ingredients, bottles, and labels. Then the Zeeh Station team makes batches and provides UW Health with hundreds of bottles of hand sanitizer every day.

“We’re very fortunate that UW Health has the procurement power to manage the raw materials and deliver them to the School,” says Elder. “We received 2,000 pump heads and bottles when we started manufacturing on March 20. We picked up more materials three days later and swapped out the whole hospital with new hand sanitizer by March 24.”

The UW–Madison Department of Chemistry donated materials on hand to support the hand sanitizer project. These included 27 gallons of ethanol, 54 liters of isopropanol, 11 liters of hydrogen peroxide, and 5 liters of glycerin.

“We are very pleased to be able to help in any and all efforts to help minimize the spread of this latest challenge to our campus and our world,” says Department of Chemistry Executive Director Matthew Sanders.

Over the long-term as the pandemic continues, sourcing could be become a challenge. “Right now, the biggest issue is availability of supplies. Alcohol is a premium product these days,” says Elder.

Like any complex project, it requires a large team effort.

“It’s quite a large operation at this point, involving technicians at the hospital who are involved in making sure everything gets here, delivery folks, and our staff,” says Elder.

The Zeeh Station team has carefully deployed resources around the lab for maximum efficiency.

“One person disassembles, cuts, and reassembles the pump heads,” explains Elder. “One person compounds batches, 10 liters at a time, and pours the mixture into a 10-liter carboy, which is basically a big Nalgene jug with a spout on it. Another person fills the 12-ounce bottles with the carboy and caps them, while someone else makes sure they’re torqued correctly and labels them.”

The hand sanitizer bottles are labeled according to FDA labeling guidelines and include the lot number and the “beyond use” date for a compounded product, which Elder says is equivalent to a “use by” date on a commercial product. The label also includes drug facts, just like an over-the-counter product would. The filled, labeled bottles are placed in a pharmacy distribution bin that gets retrieved every afternoon by a UW Health pharmacy technician.

Following safety and security protocols, the skywalk that connects the School of Pharmacy and the Health Sciences Learning Center currently provides a controlled access supply conduit for delivery of the hand sanitizer from the Zeeh Station in Rennebohm Hall to UW Hospital central supply.

“We don’t want the virus to get into the building at Rennebohm Hall,” says Elder. “We’re very cognizant of who’s around us and their health. We can’t afford not to be. We have to minimize risk to everyone.”